Seven Vermont Tech Startups Worth Watching | Tech | Seven Days

click to enlarge

Vermont will probably never rival Silicon Valley, Austin or Boston as a tech hub; its woodsy reputation is too deeply ingrained. But as a setting for tech startups, the Green Mountain State has a lot going for it — and easy access to outdoor recreation is one of them. The cofounder of IBM, Thomas Watson, famously built a plant here in 1957 because he liked to ski.

In the years since, Vermont has sprouted an impressive number of homegrown enterprises relative to its size: Mark Bonfigli was a local car guy whose desire to better control inventory and advertising inspired him to hatch Dealer.com. Kyle Clark was flying planes out of Highgate before he sketched the electric aircraft he’s trying to build at Beta Technologies. Mamava, the brainchild of Sascha Mayer and Christine Dodson, tested its first breast-pumping station in the Burlington International Airport.

As long as Seven Days has been hosting the Vermont Tech Jam, our reporters have been writing about the most interesting companies we discover in the process of planning the event. Hence, the Tech Issue. Startup enterprises, in particular, are not generally looking for publicity before they hire their first paid employees, when the founding entrepreneurs are working 100-hour weeks, spending money they’re not yet making.

Arguably, though, that is when they are most interesting and accessible.

Ken Picard’s first article about Beta Technologies, in the 2018 Tech Issue, was accurately headlined “Taking Off.” Although it’s technically still a startup — investment capital pays the bills — the company has become an industry leader in electric aviation, valued at $2.4 billion.

In other years we’ve shed light on Greensea IQ in Richmond, whose robotic submersibles scan the ocean floor miles below the surface, and Benchmark Space Systems in Burlington, whose propulsion systems guide and maneuver orbiting satellites.

It’s fun to write about startups, which aim to identify a problem and solve it for a price customers will pay. Whether the challenge is reducing bat mortality around wind turbines or offering a local alternative to Amazon, success depends on myriad factors, from the quality and uniqueness of the innovation to customer service and scalability.

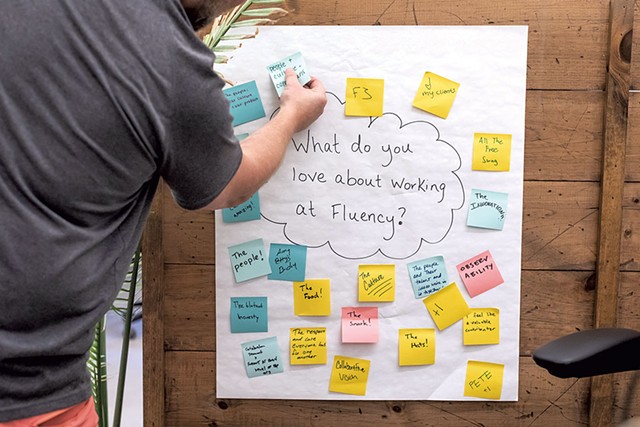

Lucky for Seven Days readers, there’s no shortage of new, innovative companies flying under the radar in Vermont for us to cover. We find them at the Jam as well as through accelerator programs like LaunchVT or early-stage investors such as the Vermont Center for Emerging Technologies, FreshTracks Capital, the Dudley Fund and Hula. Or from the University of Vermont’s virtual Entrepreneurship Forums. Sometimes we run into founders at networking events, which is how we first learned about Fluency, one of the seven startups we’re highlighting this year. It was founded by four Dealer.com alums in 2017.

“Just a little over 5 years ago I made a choice with 3 other friends to try something new. We decided to leave amazing jobs and start a business together. We laugh together, share common values, work ethics, and had an aligned vision,” Fluency cofounder Eric Mayhew wrote in August on LinkedIn.

“The subject matter of the business wasn’t totally new, but the mechanics of starting something from absolute zero, were,” Mayhew wrote. “In the beginning you have no product, no clients, and as a self-funded company, no way to collect a paycheck. You work harder than you’ve ever worked but your bank account shrinks.

“That struggle is real, but for Fluency, those days are behind us,” he went on, noting the reason he was writing: Inc. magazine had just named Fluency the 200th fastest-growing private company in the country.

“I remember bringing on our first new team-members, still without having clients. For me, personally, that was the most challenging step and yet, our growing team is the reason for any of the rest of the story.”

Read on to learn more about Fluency and half a dozen other Vermont companies that want to transform their industries, create high-tech jobs for the 21st century and, in very different ways, improve the world.

— Paula Routly

Rigorous, Wildlife Imaging Systems, FreshAir Sensor, Fluency and Myti will be exhibiting at the Vermont Tech Jam on Saturday, October 21, 10 a.m. to 3 p.m., at Hula in Burlington. techjamvt.com

Sunny Stretch

UVM-based Verde Technologies improves the solar panel

click to enlarge

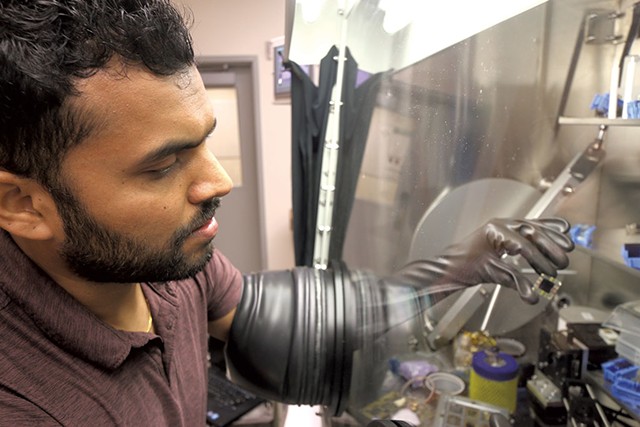

Skylar Bagdon was leading a tour of his company’s lab at the University of Vermont earlier this month when he looked down at his phone and started doing a little dance.

The CEO of solar cell startup Verde Technologies had just received an email from Joe Berry, a top scientist at the National Renewable Energy Laboratory, expressing interest in a closer partnership with the young company. The national lab was struggling to speed up production of a thin-film solar technology using perovskite and saw promise in Verde Technologies’ novel manufacturing methods.

Berry was supporting Verde’s application for grant funding from the U.S. Department of Energy.

“It’s, like, a big day!” 24-year-old Bagdon announced, beaming in his sandals and UVM T-shirt, as other Verde members gathered around to read the email for themselves.

“That is so huge, man!” exclaimed Seid Yimer Abate, a UVM research scientist working with the company, which counts just eight employees.

Berry is one of the world’s foremost experts on perovskite solar cells. He’s the leader of the Department of Energy’s Solar Energy Technologies Office and director of a consortium dedicated to making solar cells built with perovskite crystals commercially viable.

In short, as Bagdon put it, he’s “like, the dude.”

Even before Berry’s blessing, Verde Technologies was on a roll.

The company was founded in 2021 by Randall Headrick, chair of the physics department at the UVM College of Engineering and Mathematical Sciences, and Chad Miller, who built Verde’s lab at UVM and has spent a decade trying to develop more efficient, durable solar cells using perovskite.

The material, a calcium titanium oxide mineral discovered in Russia in 1839, has been used in a variety of electronics devices since the 1950s, including fuel cells and capacitors. Perovskites offer advantages over silicon when used in photovoltaic cells because the crystals react to a broader range of light frequencies, according to the Department of Energy. That means they can convert more sunlight to electricity than silicon alone.

But there have been several hurdles to commercial development. Early perovskite cells quickly degraded when exposed to moisture or oxygen, lasting just hours; to be commercially viable, panels have to last for years. The perovskite cells weren’t terribly efficient, either, achieving just 3 percent efficiency in 2009 compared to silicon’s 22 percent.

Dramatic advancements in the past decade, however, have improved efficiencies to nearly 30 percent, and research suggests some perovskite cells could last 30 years.

The real value of Verde’s thin-film cells is in their lower weight and flexibility. “That means less steel, less concrete, less labor,” Bagdon said. The promise of the product is that highly efficient, lightweight solar cells can be installed in places where other panels can’t, such as curved surfaces and roofs that are unable to support the weight of traditional panels.

One potential application is to stick new thin panels on top of existing photovoltaic solar arrays when they reach the end of their useful life, extending solar fields’ energy production without incurring additional infrastructure costs.

“What our technology provides is a pathway to cut the cost of solar in half at the system level,” Bagdon said.

Verde says its panels will be cheaper than traditional solar panels due to production methods that allow perovskite inks to be printed onto rolls of plastic membrane. In August the team tested the method on a 200-foot-long, 30-inch-wide section of panel at a high-tech coating factory in Connecticut.

Some solar cell production methods work great in the lab but can’t be scaled up to make panels at the size, speed and efficiency needed to be commercially viable, Bagdon explained. “That traps a lot of technologies in the lab that never see the light of day.”

In the case of Verde, the trial worked: The product passed the test. The patented “Verde slot coating” can create the dense, uniform layers of crystals needed to build cells that convert more sunlight to electricity, whether in the lab or the factory, Bagdon said. The company is seeking $7 million in venture funding to build a prototype cell and move toward full-scale commercial production.

Whether by partnering with existing panel makers or going it alone, Bagdon said, “We are the key that unlocks the potential of perovskite.”

— Kevin McCallum

Powering Up

Prime Engineering readies for a renaissance of advanced nuclear energy

click to enlarge

Two momentous events in the past 12 years shaped the career of nuclear engineer Benjamin Hardy, managing partner and principal engineer at Burlington’s Prime Engineering. The first occurred on March 11, 2011, when an earthquake and tsunami caused the catastrophic failure of Japan’s Fukushima Daiichi nuclear power plant. That accident, the world’s most serious since the Chernobyl disaster of 1986, nearly put an end to the U.S. nuclear industry, which had been moribund for 40 years.

The second event received far less media attention, Hardy said, but was no less consequential. On December 5, 2022, nuclear scientists achieved “unity” for the first time. That is, they created a fusion reaction that generated more power than went into producing it. Assuming nuclear researchers can cost-effectively harness fusion — the same form of energy that powers the sun — it would provide virtually unlimited clean, safe and affordable power to meet the world’s energy demands.

While that’s a big assumption, Hardy, 46, and his partner at Prime Engineering, company founder Keith Oldinski, 42, predict a renaissance of fusion and next-generation fission technology in the coming decade. In fact, with the world’s first fusion plant already under construction in Europe, Prime Engineering is now designing reactors, coolant systems and other support technologies, such as industrial cranes that service those reactors, for 21st-century nuclear plants in the U.S.

Vermonters may be surprised to learn that there’s still a nuclear industry in the state after the closure of Vermont Yankee in 2014. But in order to decarbonize the energy grid and fight climate change, Hardy said, the U.S. must diversify its power-generation portfolio. While people may disagree on what the mix of baseline power should look like and how much should come from sources such as wind, solar and hydro, 20 percent of U.S. electricity currently comes from coal plants, and another 18 percent from ’60s-era nuclear plants.

“We’re either going to replace those plants with 1960s technology,” Hardy said, “or we’re going to do something new and novel.”

Prime Engineering is doing the latter. Oldinski founded the company two years ago after leaving Hayward Tyler, an international nuclear pump and motor company with an office in Colchester, where Hardy also worked.

Today, Prime Engineering’s staff of three designs small, modular reactors and coolant systems using materials and technologies that didn’t exist in the ’60s when nuclear plants like Vermont Yankee were designed and built.

“I wouldn’t compare a 1964 car to a 2023 car when it comes to safety and everything else,” Hardy said. “I invite people to have an open mind and learn about advanced nuclear and what we’re trying to do.”

For example, old-school nuclear reactors use water as a coolant. The problem, Hardy explained, is that water remains liquid in a narrow temperature range — from zero to 100 degrees Celsius — above which it becomes a gas, expands and potentially explodes.

The systems that Prime Engineering designs use molten salt as a coolant, which remains liquid in a 1,000-degree temperature range. Not only can molten salt store more heat, Hardy explained, but it also doesn’t expand as it liquefies, thus reducing its danger, as well as wear and tear on equipment.

Prime Engineering, which is headquartered in the Vermont Center for Emerging Technologies in Burlington, isn’t building reactors or fabricating cranes in Vermont. Rather, it specializes in designing nuclear systems that comply with federal engineering codes.

The company just began hiring engineers out of college and training them as nuclear engineers. Their first is Mason Redfield, a Marlboro native and University of Vermont grad who started in June. Redfield, 22, said what attracted him to the startup was “the prospect of [working on] green energy and the opportunity to do that in the state of Vermont. It just sounded really exciting.”

Because of the potential danger of nuclear power, Prime Engineering has adopted an interesting policy in its workplace: Any engineer, regardless of rank or seniority, can challenge the conclusions of another engineer at the firm with impunity. Hardy called that “the core of the nuclear mindset, because the last thing we want is someone hiding a nuclear mistake.”

When he and Oldinski recruit, they look for engineers who “care on a different level.

“You have to be willing to accept that responsibility,” he added, “or this work is not for you.”

— Ken Picard

Force Multiplier

Rigorous’ robots automate difficult-to-fill factory jobs

click to enlarge

Rigorous cofounders Colin Riggs and Diane Abruzzini want humans to become “better collaborators with our robotic friends.”

People often equate automation with lost jobs, but the reality is more nuanced, Riggs said. His Williston-based company makes robots that can do dangerous, repetitive tasks — often jobs that factories struggle to fill for lack of willing human workers. By making industrial processes more affordable, he also sees the technology as a way to bring manufacturing jobs back to the U.S.

“There are things that humans are better at,” Abruzzini said, “and there are things that robots are better at: doing the same exact thing, every single time, on repeat, forever.”

The company’s primary product, the Box Hopper, picks up stacks of unassembled cardboard boxes and loads them into a folding and gluing machine. At Accurate Box in Paterson, N.J., humans were formerly expected to load 9,000 pounds of cardboard by hand every hour. People often walked out on the job after just half a day of the backbreaking work, Riggs said.

The Box Hopper loads more boxes, more quickly, than humans ever could. Workers who once did that physical labor are now operating the machine.

“We met a ton of the operators, and they are all our biggest fans,” Riggs said. “We’re able to take somebody who was moving 9,000 pounds an hour, and now they’re moving no pounds an hour, sitting there helping the robot do its job.”

Rigorous’ team of 10 works out of an office in Williston, where a bright yellow Box Hopper resides in a large garage. As Riggs and Abruzzini talked, the robot used its mechanical arm to draw “HELLO” in bubble letters on a piece of paper.

Riggs, 34, and Abruzzini, 36, cofounded the company in 2020 with no startup capital. This year, they raised $1.7 million through a convertible note, which banks on future equity.

“Once we had our first successful product and proof of concept in the field, we actually had a lot of people reaching out to us who wanted more Box Hoppers,” Riggs said. “At that point in time, we decided to really step on the gas.”

A University of Vermont alum, Riggs worked as an engineer at the Richmond-based underwater robotics company Greensea IQ after college. He made deep-sea autonomous vehicles, engineered robots to guide scuba divers and worked with the U.S. Navy’s Explosive Ordnance Disposal group to disarm underwater explosive threats.

click to enlarge

While land robots don’t have to deal with conditions as challenging as deep-sea robots, Riggs said his work at Greensea gave him an innovative edge.

“That experience of going all over the world and deploying robots to pretty harsh environments, I got to form this really strong opinion on the best way to do it,” he said. “When you apply that to industrial space, there’s a ton of advantages.”

Abruzzini, who runs the business side of the operation, worked on vegetable farms and started the now-closed Jeffersonville bagel bakery Mtn Seasons Woodfired before receiving her MBA from UVM in 2017.

The two share a vision to bring the efficiency benefits of automation to small and midsize businesses. This year, the company is completing a robot for Jericho Settlers Farms that rolls and unrolls row covers in greenhouses. Farmers usually lay the synthetic fabrics on winter greens for frost protection at night and take them off every morning for sunlight exposure.

“You see a lot of gantry-style robots in large-scale greenhouses, and they see a lot of efficiency from that,” Abruzzini said. “We said, ‘What if we took that concept, and we scaled it down and right-sized it for Vermont sustainable farms?'”

Next year, the company plans on launching a robot that can take parts in and out of injection molds, commonly used to manufacture plastic items. While such robots already exist, Rigorous’ will have a sophisticated level of customization, Abruzzini said, such as the ability to add labels or trim certain pieces.

Robots helping humans with industrial tasks may not make for a thrilling sci-fi movie, but Riggs hopes it at least makes for good business.

“People have this idea of robotics as this kind of AI, humanoid thing that walks around and talks to us, but I think there’s a lot of really valuable stuff in just industrial robotics,” Riggs said. “It’s really impactful for a lot of people.”

— Hannah Feuer

Flight Risk

Brogan Morton’s Wildlife Imaging Systems helps make wind energy safer for bats

click to enlarge

Wind turbines earn points for harnessing renewable power and cutting carbon emissions, but their giant rotating blades — and perhaps the pressure variations they cause — kill hundreds of thousands of bats each year.

Bats control pests, pollinate plants and disperse seeds. They eat enough insects to save U.S. agriculture more than $3 billion a year in crop damage and pesticide costs, according to the U.S. Fish & Wildlife Service. In short, they are an essential part of the ecosystem. Wind developers pay steep fines for killing certain species.

Brogan Morton wants to protect bats and keep turbines turning. He was product manager at NRG Systems when the Hinesburg-based wind and solar measurement company developed a bat deterrence system with Bat Conservation International. Because bats emit high-frequency calls and use the echoes to determine the location of prey and obstacles, the team built an ultrasonic device to interfere with their communications. The idea was to make echolocation so difficult around turbines, the bats would fly away.

Early product testing was encouraging. Developers mounted the device on turbines, then compared the number of dead bats to those at turbines without. “It worked,” Morton said. But making the product better required knowing more about bat activity around the turbines. Nobody provided that service, Morton said, “so I decided to do it myself.”

The company he built, Wildlife Imaging Systems, can turn hours of bat videos into data. Wind operators can learn how many bats circle their turbines, the time of night and the seasons in which they are most active, and the most effective spot for a deterrent device.

Companies will stop turbines to avoid killing protected species. Additional knowledge helps them schedule the shutdowns wisely, when bats are most vulnerable.

Companies working with Wildlife Imaging run thermal-imaging cameras for 15 hours daily — mostly at night — for five or six months spanning spring and fall migration seasons. They upload their footage, and Wildlife Imaging’s software detects bats and counts them. For every 10 minutes of video, it creates a summary image — similar to a time-lapse photo — to show how the bats are moving.

click to enlarge

Wildlife Imaging is currently monitoring more than 100 cameras in 15 projects across the U.S. and Canada, none of which is in Vermont. Next summer, the company will test its 3D-imaging system at an offshore wind site in the North Sea.

Morton started the company in January 2020. Backed by nearly $2 million in small business innovative research grants from the National Science Foundation and the U.S. Department of Energy, he has sold his product to wind developers and continued to refine it with their input. “That’s allowed us to grow a little bit more slowly because we don’t have to develop this enormous solution and then bring it to market later,” he said. “We can kind of codevelop it … and still get paid.”

The arrangement is mutually beneficial. Wind developers are financially motivated to reduce the number of bats they kill. The federal Endangered Species Act protects 12 species. Some states protect additional bats.

For his part, Morton is hoping the Fish & Wildlife Service, the agency that regulates the Endangered Species Act, recognizes his method of collecting bat activity as the “best available science.” That stamp of approval would encourage wind developers to cite his data in permit applications and bat mortality mitigation plans.

Demand is bound to grow. Government investment in clean energy — provided by the Inflation Reduction Act and the Bipartisan Infrastructure Law — has “turbocharged” the renewables industry, Morton said. Between 2020 and 2030, the Department of Energy expects wind-generated electricity to double.

But more wind turbines put more bats at risk. The flying mammals appear to be attracted to the turbines, “and no one’s really quite sure why,” Morton said. He’s part of a separate research project seeking those answers.

Morgan works in Hinesburg with three employees and a goldendoodle named Baker. Wildlife Imaging is headquartered in a strip mall, next to a nail salon. “I can say that our office is quite boring. Lots of headphones and coding,” he warned in an email before our interview. His tune changed when I got there. He opened the door and announced, “This is where the magic happens.”

— Mary Ann Lickteig

Smoked Out

FreshAir Sensor detects cigarette, marijuana smoke in hotels

click to enlarge

Brazen guests looking to smoke in hotel rooms have long had a reliable method of evading detection: not getting caught in the act.

Suspicious hotel management lacking concrete physical evidence may only be able to point to a lingering stench. As a result, hotels frequently lose disputes over smoking fines.

The Lebanon, N.H.-based startup FreshAir Sensor is looking to change that through devices that detect cigarette and marijuana smoke in real time. Unlike a traditional smoke detector, FreshAir Sensor only reacts to tobacco or marijuana smoke — not smoke from candles, incense or steam. The Wi-Fi-connected device sends time-stamped data on any smoking activity to the client via email. Armed with scientific evidence of smoking, hotels can more easily collect smoking fines and deter guests from lighting up.

Jack O’Toole, an alum of Dartmouth College’s Tuck School of Business, cofounded the company in 2013 with Dartmouth chemistry professor Joseph BelBruno. The chemist had pitched his nicotine detection technology to O’Toole’s Intro to Entrepreneurship class, and O’Toole quickly recognized its commercial potential.

“As soon as I heard he could detect nicotine, I immediately thought about smoking in hotel rooms,” O’Toole said. “There’s a chain of hotels I refuse to stay in because, twice in a row, I got rooms that were smoked up.”

FreshAir Sensor’s customers include Hilton Miami, Bally’s Atlantic City Casino Resort and Mohegan Sun. Property management for apartment complexes and public housing have also bought the patented sensors.

FreshAir notifies clients of suspicious activity once it’s 95 percent confident someone is smoking. Customers have full discretion over how they respond: For example, casinos may choose not to charge or kick out a smoker if the person in question is a “high roller,” O’Toole said.

The technology is reliable enough that data from FreshAir Sensors have successfully been used in court as evidence of smoking in eviction cases, he added.

Achieving such a high degree of accuracy took five years of testing before the sensors hit the market, O’Toole said. In one of his first trials, he paid a Dartmouth junior $20 an hour to smoke cigarettes. Recognizing that human testing might raise eyebrows, O’Toole soon developed a machine to simulate human smoking instead.

“I don’t think her mom would have been too thrilled,” he joked.

Now the FreshAir Sensor team of almost 40 works out of a dog-friendly office in Lebanon with neon green walls that O’Toole said give the space a “Silicon Valley feel.” Overseas FreshAir workers based in Pakistan, Colombia and Ireland also contribute to development and quality assurance.

click to enlarge

In October, Business NH Magazine rated FreshAir Sensor the seventh-best place to work in the state. O’Toole said he fosters a culture where employees aren’t afraid to experiment and have fun. The company hosts an annual “pancake biathlon,” at which FreshAir employees eat as many pancakes as they can before running up and down Moose Mountain in Hanover. There’s a 15-minute bonus for each whole pancake consumed, all of which is lost if the pancakes come back up. “No partial credit,” O’Toole said with a matter-of-fact tone.

Nick Rassias, a FreshAir hardware engineer, interned at the company for two summers in college before joining full time. On his desk is a miniature Hogwarts skyline and a melting Rubik’s Cube, trinkets he said he 3D printed in the office on weekends.

“They give us a lot of freedom to kind of explore the possibilities of whatever we’re working on,” he said. “It’s a great environment. Everybody’s super supportive.”

FreshAir hopes its next product, currently being tested in some Upper Valley schools, is a sensor that can detect vaping. Educational institutions will be the target customer since vaping doesn’t result in the same stench or property damage as cigarettes and marijuana, O’Toole said.

The sensors are good for business, but they’re also about encouraging healthy living. “We certainly don’t want kids vaping,” he said. “We don’t need another generation of people addicted to nicotine.”

FreshAir has 12 patents and eight pending. Another invention in the pipeline: a material that can permanently capture hydrogen sulfide, a colorless gas that makes sewage treatment plants and landfills smell like rotten eggs.

“We’re just grateful to be able to grow our company here in the Upper Valley,” O’Toole said. “We’ll keep developing sensors and industrial materials that detect or capture bad things to help protect people.”

— H.F.

Speaking the Language

Dealer.com alums simplify the digital advertising process at Fluency

click to enlarge

Dealer.com cofounder Mike Lane helped grow the Vermont company into a leading digital marketing services provider for the automotive industry. When Dealertrack Technologies bought it in 2014 for nearly $1 billion, Lane cashed out. His coworkers Eric Mayhew, Scott Gale and Brian McVey stayed on for another three years, through a second sale. In 2015, Cox Automotive bought Dealertrack for $4 billion.

Instead of heading for the golf course, however, the foursome teamed up to start another tech company. Fluency incorporated in 2017. Two months ago, it made Inc. magazine’s list of the 5,000 fastest-growing private companies in the U.S. The list ranks companies based on revenue growth over a three-year period. Between 2019 and 2022, Fluency’s revenue grew 2,747 percent, which ranked first in Vermont, ninth in New England and 200th in the country. The self-funded Burlington company employs 75 people in 18 states — half of them in Vermont.

Fluency automates the tedious tasks required to run and manage ads online. Its clients are large digital advertising firms and Fortune 1000 companies with in-house marketing that handle accounts in a variety of industries: automotive, apartment rentals, real estate, home services, insurance, wedding venues and franchises such as fast-food chains.

The company uses robotic process automation, a way of using software to perform mundane, repetitive office tasks at high speeds. A pioneer in applying this type of automation to digital advertising, Fluency takes data supplied by advertisers, enters it and builds ads that can run on a number of channels, such as Google Ads, Facebook and Bing. In January, the company integrated artificial intelligence into its platform to help advertisers generate keywords, headlines and ad copy.

Take apartment rentals, for example. An agency’s client may own multiple buildings containing hundreds of apartments. When a unit opens up, the company wants an ad — on a number of sites — touting all of its relevant features: square footage, hardwood floors, lake views, pet-friendly, shared pool.

Before Fluency, some account managers typed in every detail of every apartment into every advertising platform. Limited automation existed to help, but there was still a lot of typing. “It’s really not fun work,” Lane said. They spent their days copying data from Excel sheets. “You’d be like, I have a thousand rows to cut and paste into Google. It’s gonna take me 15 hours to do that … People are going fast and making mistakes.”

click to enlarge

When an account manager uploads data to Fluency, the software fills in those fields and can tailor ads for specific markets. Once the ads launch, Fluency can flag errors, track performance across channels and reallocate spending. Advertisers can monitor all of their campaigns on a single platform.

Ad strategists, who could previously handle about 30 accounts, can suddenly wrangle up to 10 times that many, Mayhew said. “They’re super-powered with the tool.”

While they were still working for Dealer, Mayhew, Gale and McVey shared a dream to become entrepreneurs. They met discreetly, they thought, to exchange ideas. “We thought we were sly … going to Trader Duke’s at six in the morning,” Mayhew said.

One morning, Lane happened to be there for a Vermont Workforce Development Board meeting; he’d left Dealer by then. “Mike walks over,” McVey said. “He goes, ‘I don’t know what you’re doing. But whatever it is, I want in.’ And he walked away.”

Later, when Dealer was offering buyouts to employees, McVey accepted. Over beers at Switchback Brewing, he encouraged Gale and Mayhew to do the same: “If you’re not going to do it now, how can we call ourselves entrepreneurs?” Gale walked out of the bar, called his boss, walked back in and said, “All right. It’s done.”

Minutes later, Mayhew gave notice.

They began meeting regularly with Lane to discuss what sort of business they might start. “Some of them were way out of our skill set but interested us, like alternative energy or robotics,” Mayhew said.

They homed in on digital advertising, something they’d handled at Dealer. “Dealer.com’s mantra of scalability kind of got ingrained into all of us,” Mayhew said. They applied it to advertising. “As we looked at platforms that were out there, we realized that nobody was thinking that way. And we said that we should bring that to the world. We should bring scalability and efficiency in advertising to the world.”

— M.A.L.

Prime Mover

Local Amazon rival Myti goes live to keep e-commerce dollars in Vermont

click to enlarge

When Bill Calfee announced in 2020 that he was creating a local alternative to Amazon, he faced a healthy dose of skepticism. Having no prior experience working in the tech sector, Calfee planned to take on the world’s fifth-largest company, whose name is synonymous with e-commerce. That he had the chutzpah to call it Myti — pronounced “mighty” — suggests Calfee had some idea of what he was up against.

But Calfee also had his share of supporters, including deep-pocketed investors. Many consumers detest Amazon and, if given a choice, would prefer to spend their money at local businesses if the price, convenience and delivery times were comparable to those Amazon offers. The problem was, for many items, consumers had few if any alternatives.

Until now. Beginning in early October, shoppers who live in Chittenden County can visit the Myti website and, without having to pay a membership fee, buy goods from at least 24 Vermont retailers — what Myti refers to as its “shops” — including Homeport, Brio Coffeeworks and Small Dog Electronics. Those products, which range from books to pet supplies to sporting goods, will then be delivered to consumers’ homes or businesses in Chittenden County, via Myti’s fleet of all-electric vehicles, in two days or less.

Local business owners, whom Myti calls “shopkeepers,” pay only a modest transaction fee on each purchase. But unlike Amazon, which maintains massive fulfillment centers around the country, Myti digitally searches the stockrooms of its member shops using a shared inventory-management tool. When a consumer buys an item through Myti — say, fuzz-lined Crocs from Lenny’s Shoe & Apparel in Williston — the company’s software automatically adjusts Lenny’s inventory to reflect that purchase. Consumers can either pick up the item in person or have Myti deliver it to their doorstep.

The goal, Calfee explained, is twofold. First, he wants to reduce the huge environmental impact of buying through Amazon. The mega-retailer routinely ships products thousands of miles and often sends returned items straight to a landfill because it’s cheaper than restocking them. Myti’s returns, which are free, go back to the store of origin.

Second, Calfee wants to keep Vermont’s e-commerce dollars in the state and supporting the local economy.

“Vermonters are spending $20 per second with Amazon,” Calfee said, citing recent sales figures from the Vermont Department of Taxes. “We’re sending half a billion dollars out of our economy [each year]. It’s horrifying.”

But Calfee envisions Myti as being more than just an Amazon rival. Part of the company’s mission is to serve as an information clearinghouse, providing local shopkeepers with data on consumer buying habits so that they can stock items Vermonters routinely purchase.

Recently, the company launched its Myti Concept Shop, which offers items that shoppers regularly search for but aren’t carried by Myti’s member stores. For example, because no Myti shop currently carries 20-count packs of AA batteries, Myti lists that item under its Myti Concept Shop, then purchases it through a local retailer not yet linked to Myti.

Ultimately, Myti’s intention is for one of its member shops to recognize the demand for that item, then stock it in its own inventory. Said Calfee, “We want enough items on the platform so that people feel like they can find anything [they need] here.”

Though Myti has begun testing its market outside of Chittenden County, Calfee wouldn’t disclose where its services will be available next.

That said, when central Vermont was hit by severe flooding in July, Calfee was frustrated that Myti wasn’t prepared to assist. As he explained, if Montpelier retailers had inventory stored elsewhere, Myti’s technology could have helped those stores maintain their cash flow.

“When Bear Pond Books was flooded, their customers were faced with the problem, ‘Where do I get a book?'” Calfee said. “If they started buying that book from Amazon, once Bear Ponds reopened, they have to get that customer back again.”

Similarly, when Bed Bath & Beyond closed its Williston outlet, it created a void for people who routinely shopped there for home goods.

“We’re frantically loading sheets and towels and shower curtains” on the Myti Concept Shop, Calfee said, “trying to fill that void.”

Thus far, Myti hasn’t enabled one feature it initially promised: a live video chat function that would enable shopkeepers to speak with online customers and answer their questions. That feature is still in the works.

Asked what he’s learned from his three-year startup experience, Calfee thought a moment, then said, “It’s hard.”

— K.P.